Metal bellow seals offer distinct advantage in high temperature application. A bellow core constructed by welding number of metal diaphragms together eliminates the need for springs, providing more flexibility to the seal face compensating for seal face wear.

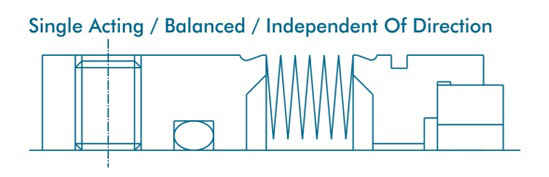

SERIES: AMMBO

Series AMMBO are widely used in refining, petrochemicals and chemical industries. Static o-ring is used as a secondary member. The absence of dynamic o- ring prevents possibility of seal hang-up. Centroid loaded face design increases seal life by avoiding seal face distortion caused due to thermal expansion and also ensures optimum face flatness over a wide operating condition. As a standard, AM350 bellow cores are used. For chemical compatibility Alloy C-276 or Alloy 718 bellow cores can be used.

- Single Seal

- Balanced

- Metal Bellows

- Independent on direction of rotation

- General chemicals

- Petrochemicals

- Refineries

- Shaft Diameter - d1 : 18…100mm

- Pressure - p : 22 bar (max)

- Temperature - t : -20…220°C

- Velocity - v : 20m/sec

- Seal Faces : Ceramic, SIC, Tungsten Carbide

- Metal Parts : SS304, SS316 Carpenter 42, Hastelloy-C, Alloy20

- O-ring: Elastomers, PTFE

SERIES: PTMBG

Series PTMBG seals specially designed for high temperature application and suitable for high startup toque since the bellows unit is independent of torque transmission. Grafoil is used as a secondary member having excellent temperature range upto 400°C. Shrunk fit seal face design minimize face distortion restricting leakage and wear rate to very low level under a wide range of condition.

- Single Seal

- Balanced

- Metal Bellows

- Independent on direction of rotation

- High temperature applications

- Petrochemicals

- Refineries

- Shaft Diameter - d1 : 18…100mm

- Pressure - p : 20 bar (max)

- Temperature - t : -20…220°C

- Velocity - v : 20m/sec

- Seal Faces : Ceramic, SIC, Tungsten Carbide

- Metal Parts : SS304, SS316 Carpenter 42, Hastelloy-C, Alloy20

- Packing: Grafoil